How Thermal Vacuum Test Chambers Ensure Your Product Quality

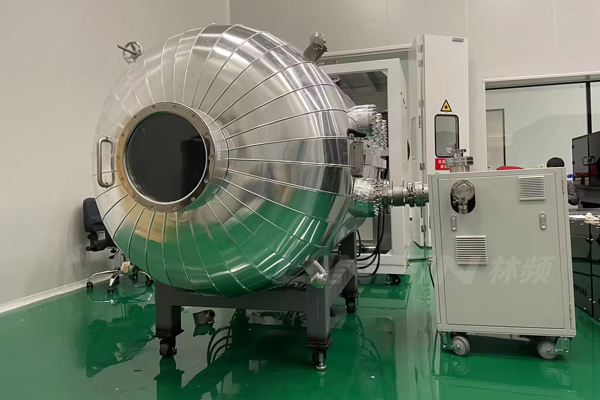

Author:LINPIN Update Time:2025-09-02 Source:LINPINA thermal vacuum test chamber is a specialized device designed to evaluate product performance and reliability under extreme high-temperature and vacuum conditions. By simulating space, high-altitude, and other harsh environments, it helps guarantee your product quality and gives you a competitive edge in the market.

Here’s how thermal vacuum test chambers ensure your product quality:

-

Performance Validation

Testing under high-temperature and vacuum conditions allows you to verify product durability in extreme environments. This ensures heat resistance, sealing integrity, and material/component reliability, confirming your product performs optimally in real-world applications. -

Reliability Assessment

Thermal vacuum chambers help assess product reliability and lifespan. By exposing products to simulated stress conditions, potential defects or failure points can be identified early, enabling design and manufacturing improvements for enhanced durability.

-

Product Optimization

Testing in thermal vacuum chambers reveals performance issues under extreme conditions, allowing targeted refinements. This process enhances product functionality, reliability, and adaptability to better meet customer and market demands. -

Regulatory Compliance

Certain industries require products to meet strict compliance standards. Thermal vacuum testing ensures your product adheres to relevant regulations, facilitating necessary certifications and approvals.

Thermal vacuum test chambers provide robust quality assurance by validating product performance in extreme environments and driving design improvements. By leveraging this technology, you can deliver superior, market-ready products that earn customer trust and satisfaction.